Do you spend your nights dreaming of what goes into the planning and building of a mixed-use manufacturing, watch-building, and office space?

We’re sure that you do!

But if you answered “No,” we totally understand where you are coming from. Until recently, we were in the same boat as you, but with great expansion — and the desire to grow the only American-made watch company — comes much learning.

Vortic Watch Company has been going through massive changes at our new space on Jefferson Street in downtown Fort Collins, CO. Even though we’re experienced painters, we do not know the building code by heart, which has provided us with some twists and turns along the way.

From learning how to make the fire department happy to understanding the permit acquisition process, our knowledge of industrial construction is growing by the second.

Who knows? We may need to add “Construction Site Foreman” to our resumes by the end of this renovation!

If you’re interested in what we do at Vortic, how our expansion plans are going, and what the future holds for our new building, stick around for this Custer & Wolfe article. We’ll take you behind the scenes of our new American machine shop and talk a bit about the exciting plans we have for the future.

The clock is ticking, so let’s get started!

Welcome to the New Home of Vortic Watch Company

There have been many phases of the Vortic Watch Company. We’ve worked everywhere, from the basement at R.T.’s house, to a tiny building in an artisan village, to our current facility. So it’s safe to say that we know how to improvise, adapt, and overcome when it comes to watchmaking.

However, after spending years working in facilities that only meet our needs for a short time, we can proudly say that we’ve found a place that will give us a chance to operate and grow comfortably. Our new Jefferson Street facility has the space and the infrastructure we need to keep things ticking at Vortic for years to come.

The American Machining Shop of Our Dreams

We desperately needed two things in our new manufacturing and production facility: space and electrical capacity. Thankfully, our new location delivers on both.

We recently worked with the city to install a massive upgrade in the building’s electrical system. By massive, we don’t mean jumping from a 100 to 200 amp service. We boosted the machining facility at our new location to 1,000 amps, which is about five times what we have right now.

That amount of power allows us to expand our machining capacity and develop an even better quality product.

“We’ve upgraded the power service on the building from 200 to 1,000 amps to energize all of our machinery, and we actually had to dredge a wire across the street to upgrade our service. We’ve also got a huge upgrade [in shop space] over what we have now. The current machine room is about 500 square feet or less, and here we have 2,300 square feet of usable floor space.” – Tyler Wolfe

In addition to having the power to scale up our production, we now have enough space to stretch our legs while we’re working — 8,400 square feet of it, to be exact. This size doubles our current facility, and in addition to exponentially more manufacturing space, it allows us to create something we’ve always dreamed of having — a wholly dedicated cleanroom.

Our Biggest Project Ever: The Cleanroom

For those of you who don’t know what a cleanroom is, we’ll give you a quick rundown. A cleanroom is a space that utilizes ventilation and filtering to keep it free from dust and other contaminants — if you need a visual, the lab in Jurassic Park is a great example.

We created a makeshift cleanroom with small HVAC units and a dedicated room in our old Link Lane facility, but now we can go all out. Our new cleanroom will give our watchmakers plenty of room to work and feature state-of-the-art equipment like a Liebert air scrubber unit that regulates temperature, humidity, and the air pressure inside the room.

“We’re adding a fancy Liebert air scrubber unit … so as we’re assembling, we can make sure that no dust is getting inside of the watches. [And] it’s also got humidity control to ensure the watches have the perfect amount of humidity inside them. So when they go to say, Florida, and you get a rainstorm, there’s no condensation inside of the watch.” – Tyler Wolfe

Our new cleanroom will also have an airlock. You know — like the series of rooms on the space station that makes it possible for people to go from outer space to an air-filled environment. Only, we won’t be pumping in air to give us the ability to breathe — we will be doing it to keep the cleanroom dust-free and without any foreign contaminants.

“Having the airlock is one step of removal from the dust of the outside world. … Once you enter [the first room], we’ll have different sets of shoes and lab coats [to prevent] the dust on your clothing and street shoes … from entering the cleanroom.” – Tyler Wolfe

Building a dedicated cleanroom allows us to restore watch movements and build watches at the highest level possible. The controlled environment makes the watch-building process even more precise, and it ensures that the parts we build for the watches remain within proper tolerances.

Extreme Makeover: Commercial Building Edition

If you’ve ever watched HGTV, you’re familiar with the extreme makeover format.

An over-enthusiastic host — who may or may not be a super-talented carpenter/interior designer — ambushes an unsuspecting family. Then, the family visits a theme park or goes on a dream vacation for a week while a crew completely guts and rebuilds the house.

If you’ve been keeping up with our progress, you may be seeing a few of those demo day to finished product parallels, but there’s something HGTV doesn’t show — the actual process.

Honestly, we’re skeptical of the time frame those remodeling miracle workers claim to keep after dealing with all building, electrical, and fire codes/permits in our area. Every step of the way, there’s a new permit you need to acquire and an incredibly long list of details you need to follow for your building to be up to code.

Roadblocks or Codes & Permits?

Everyone who has built a new home or decided to build a garage in the backyard can probably sympathize with our situation. We were ready to start demolition on day one of purchasing our Jefferson Street location, sledgehammer in hand, but our better judgment told us to go through the proper channels first.

We’re glad that we did, but we had no idea that there would be so many regulations we needed to build our dream machine shop.

“Pro tip: Don’t renovate things. It’s super, super intense, and I think the biggest issue we’ve had here is permits in general. And it’s not necessarily the city of Fort Collins’ fault. There’s just so many things you have to do to get a permit — especially in an 8,000 square foot building.” – R.T. Custer

We needed to follow a seemingly infinite number of regulations to ensure everything was up to code, from building sidewalks to choosing the proper ramps and doors to keep the entire facility ADA compliant. And it seemed like we ran into issues every step of the way.

Cool Buildings Aren’t Always Move-in Ready

One thing that drew us into our new facility on Jefferson is the fact that it’s straight-up a “cool building.” The building is right in the middle of downtown, it’s interesting, and there was just a cool factor that drew us in.

However, because it’s an old building, the new Vortic HQ has come with its fair share of obstacles. And in hindsight, there were two things we probably should have been more diligent about when looking for a new space.

“Number one is this building is really cool, interesting, and in downtown Fort Collins. But, it is an interesting building that has been added to, modified, and rewired multiple times, so there have been some interesting situations so far.” – Tyler Wolfe

When we think about it, “interesting” might not be the right word for how the wiring and plumbing have treated us. There were different regulations with every expansion, which meant we needed to go through all of the previous work to ensure it was up to today’s standards.

These updates led us to the second thing we should have thought of as we looked for a new space:

“The second thing we’re doing is changing it from business use to factory use. So we’re changing the occupancy, which triggers every code inspection in the book. And one of our major hurdles that we missed in our first round of architectural drawings was getting up to fire code.” – Tyler Wolfe

As you can imagine, there’s no wiggle room with the fire department, which means we’ve learned a lot about fire code. One of the most significant things we didn’t realize that we needed were special firewalls between our manufacturing and office spaces, which turned out to be a much larger project than we anticipated.

After a three-to-four-month project we weren’t expecting, our plans are finally where they need to be. Everything is approved, and we are about to make some massive changes: We’ve got some sledgehammers that have been calling our names for months.

Exciting Things Are Coming at Vortic

Our new facility on Jefferson Street is a massive upgrade for our machining capabilities, quality control, and even our video production ability. We’re counting every second until we can move into our new building, and we want to bring you along for the ride.

We couldn’t fit all the details from this episode into our article today, so be sure to watch episode three of Building a Watch Company, Out With the Old: In with the New Shop + Clean Room. Trust us. It’s got everything you’re looking for in commercial building renovation and American machining shop content.

To stay up to date with all things Vortic and watch our progress as we build out the new manufacturing and watchmaking space, subscribe to the Custer & Wolfe YouTube Channel. We’ll have bi-weekly videos that keep you in the know about everything going on here.

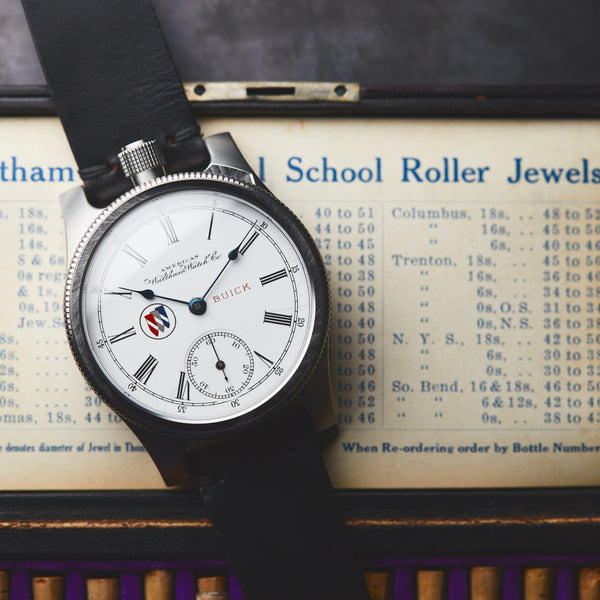

And if you’re interested in the reason behind our YouTube channel — our artisan watches built from historic pocket watches — be sure to check out the Vortic website and follow us @vorticwatches for our watch of the day.

As always, thanks for coming along for the ride — we’ve had a great time.