What is a “railroad grade” pocket watch?

A railroad grade pocket watch is simply a watch that was approved by a particular railroad organization for use by conductors on their rail. The specific definition of a “railroad grade” watch evolved quite a bit over the years. And, contrary to common belief, there were many regulations in place before Webb C. Ball was commissioned by railroad officials in the 1890’s to create an overarching set of railroad watch qualifiers.

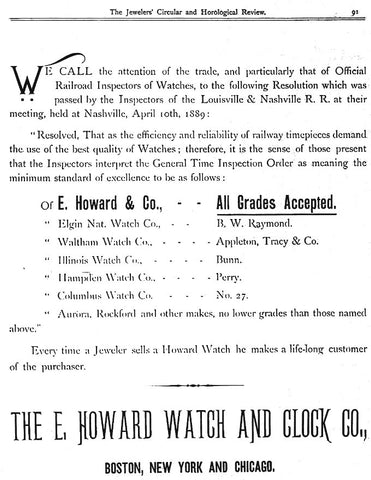

Before the 1890’s, and until the entire railroad industry accepted Ball’s standards, different railroads had different qualifiers for watches. One rail may have had a list of accepted makes and models of timepieces while another may have only listed necessary features or timekeeping performance thresholds. This makes evaluating older watches as railroad grade a very difficult task, i.e. a watch may have met the standards of one company but not another.

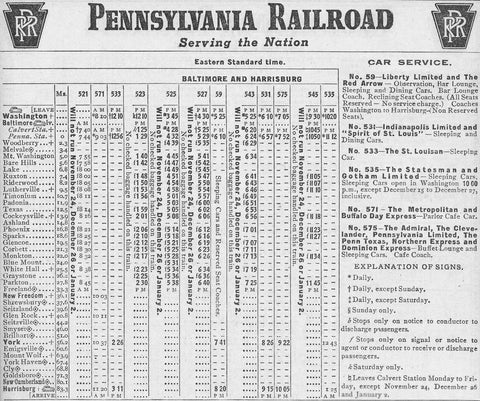

As the rail industry grew in the United States, the number of active trains grew with it. In order to use the track efficiently, companies needed to create time schedules identifying when each section of the track was safe to use. The timekeeping accuracy of the conductor’s watch was crucial if two trains were moving in opposite directions. If one of the two conductors’ watches was keeping bad time there was a strong likelihood of a collision. Railroad watches were known as “standard” watches because they met the railroad’s standards of timekeeping. Talk about a lot relying on a single piece of equipment! Timepieces were clearly an important aspect of ensuring safety for all.

What were the most common features of railroad watches?

The watches that we have come to know as the “best” railroad watches were made after 1900. At this time both the watch companies and the railroads were hitting their stride in terms of volume and quality. An important part of standard watch regulations included service intervals and testing, but there is also a list of features that almost all railroad watches shared.

Perhaps the most prominent feature of 1900’s railroad watches is their lever actuated setting mechanisms (referred to as "lever-set"). Most watches are put in time-setting mode by pulling the crown (winding knob) away from the watch, then pushing the crown back towards the watch to return to winding mode. This is referred to as "pendant-set."

A lever-set mechanism requires the user to remove the bezel of the watch and engage a lever to place the watch in setting mode. This tedious process of removing the bezel of the watch had a very important purpose; it ensured that the time on the watch was never accidentally changed by catching the winding knob on a pocket or any number of other unintentional situations.

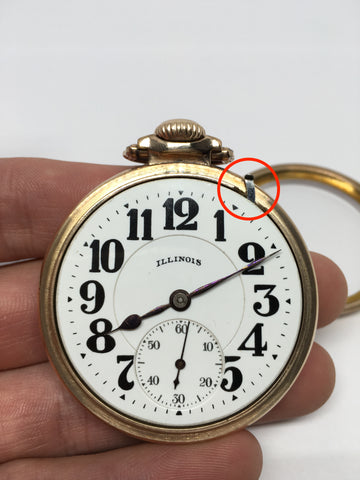

Another iconic feature of railroad watches is their big, bold, black, Arabic numerals on highly contrasting white enamel dials with large bold hands. This feature made telling the time as clear and easy as possible while creating a distinctive and functional railroad watch aesthetic. Many individuals would agree that railroad watch dials were some of the most beautiful watch faces of the time. Although, we tend to think the watched manufactured here at Vortic Watch Company would give them a run for their money.

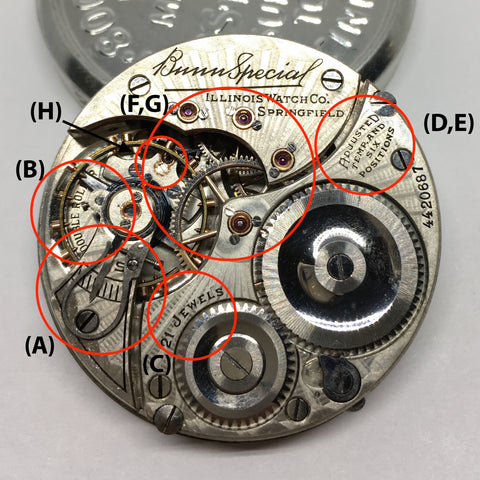

Mechanically speaking, almost all 1900’s railroad watches shared a number of performance and reliability enhancing features. Most had a fixed regulator to avoid timekeeping variation from impact (A), a double roller balance wheel to avoid going out of action (often called overbanking) (B), 19 or more jewels to reduce friction and increase consistency of the gear train (C), timekeeping adjustment in 5 or more positions to make sure the watch kept accurate time regardless of orientation (D), and adjustment for temperature to ensure accuracy in a variety of climates (E). Many railroad watches had solid gold or gold plated gear trains (F) and jewel settings (G) to reduce the effects of magnetism as well as reduce tarnishing, and later watches had features such as magnetically resistant balance wheels, Elinvar hairsprings, adjustments for isochronism, and advanced cap jewel covers (H).

Some of the highest end railroad watches featured what was referred to as an up-down wind indicator. This is called a power reserve indicator on modern watches, and it visually communicates how much wind remains in the watch on a sub-dial at 12 O’clock. This feature did not necessarily improve the timekeeping performance of the watch, but it is convenient to be aware of how much wind is left on the watch to avoid letting the watch run out.

What is Vortic’s Railroad Edition?

Vortic’s new “Railroad Edition” watch is designed to accommodate the geometry and functions of railroad watches, primarily the lever-set mechanism. The Railroad Edition watch case features a 3-piece design with an easily removable cam-lock bezel to access the lever. The cam-lock function makes setting the time much easier than original railroad pocket watch cases, and it allows for a water tight seal when fully engaged, keeping your watch safe and functional.

Note - these are rough prototype images

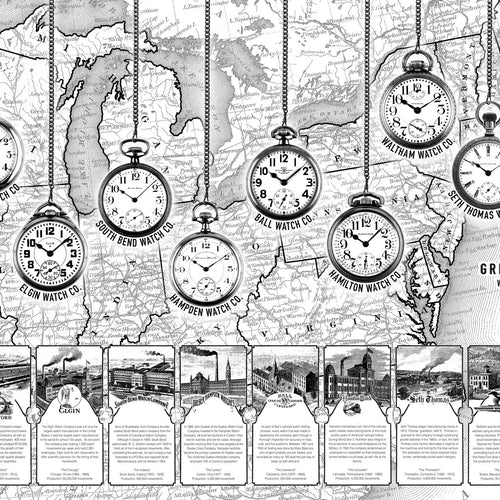

At Vortic Watch Company, we are focused on restoring and preserving some of the most famous railroad watches of all time such as the Hamilton 992B, Ball 999B, Illinois Bunn Special, Elgin B.W. Raymond, Waltham Vanguard, and much much more.

If you're interested in a Railroad movement, and want to secure your very own wristwatch from our Railroad Edition Collection visit our watch page. Or, you can explore converting your existing pocket watch if you want something that is more personal.

We hope you enjoyed this blog and make sure to post any comments or questions in the comments section!

Regards,

-The Vortic Watch Company Team