What makes a business successful?

Is it the amount of revenue it makes? Or perhaps it’s the quality of the company's products.

Here at Vortic Watch Company, success means creating high-quality, American-made watches. One challenge we face is having the time to create and implement our company’s big-picture goals. Fortunately, we have the privilege of working with incredibly talented and knowledgeable employees who enable us to plan out and accomplish our company's goals.

As we grow our operation, we want to continue sharing updates and insights about the watchmaking process and how to expand a small business. That's why we, R.T. Custer & Tyler Wolfe, created our Custer & Wolfe: Building a Watch Company YouTube channel and article series.

In this episode, we discuss the importance of getting the right tool speed for chip formation, progressing toward our long-term goals, 3D printing, and using grant money to help us grow.

Importance of Tool Speed in Building Vortic Watches

Machining is a complex process that involves many intricate processes, and it just gets more complex when you layer that with the small parts we create for our watches.

We need our tools to spin at certain speeds depending on what we are trying to accomplish and the tool's size. Some of the machines that we use to produce our tools and watch components include our Haas CL1, Haas ST-20Y, and our DMG Mori Sprint 20 Swiss machine.

When using small tools, we need the revolutions per minute (RPM) to be faster than if we used a larger tool. This is because the edge's speed will be faster on a larger tool than on a smaller one.

"The first thing you have to understand is that the RPMs are the same whether it's a big tool or a small tool, but with a big tool at the same rpm, the speed at the edge of the tool is faster the further away you are from the center of the spindle. … Same thing with a lathe. [With] larger material, you can spin it slower. [With] small material, you have to spin fast." - Tyler Wolfe

The further away the tool is from the center of the spindle, the faster it will be. This means that a larger tool will go faster than a smaller tool if they're functioning at the same RPM.

"If we're cutting with a large tool, we may only have to spin it at 500 or a 1000 or 2000 RPMs to get the optimal cutting conditions because the speed at the surface of the tool is fast even though the RPMs are low. [The] smaller [the] tool you get, the faster you have to spin it to get that same surface speed at the edge of the tool" - Tyler Wolfe

Picture two tires and one tire is significantly larger than the other. If they have the same RPM, which will be faster? It will obviously be the larger tire because it covers a greater surface area, so it achieves a greater distance than the smaller tire with every revolution. The RPM for tools works similarly.

Using the Right Speed for Proper Chip Formation

When machining, you need to obtain a particular speed to ensure proper chip formation. Chip formation is the way in which the tool cuts the material:

"We're always talking about chip formation, creating the correct chip. We don't want to be rubbing the tool against the material and making dust, and we don't want to be slamming into the material too hard." - Tyler Wolfe

Fortunately, we don't need to calculate the speed at which to obtain proper chip formation with our machines. Instead, the machining equipment companies provide that information.

"All these tools come with data sheets from the companies that we buy from, so we have an idea for the optimal cutting conditions for different materials. We work with a lot of titanium, which is very sensitive to these cutting conditions." - Tyler Wolfe

When it comes to milling and lathing, you want to use smaller tools to maintain an ideal surface speed for the chip formation:

"[We use] smaller tools to maintain the surface speed, … [and this creates] the best chip and the cleanest cut to create the most consistent finishes and geometries." - Tyler Wolfe

Fortunately, we can get a great speed with our DMG Mori Sprint 20 Swiss turning center, which is capable of performing 10,000 RPM.

We’re Making Forward Progress Toward Larger Goals at Vortic

One thing you may notice about this Custer & Wolfe article is that we're not discussing any significant setbacks like in previous entries. Much to our delight, the reason why is because things are going incredibly well overall. We haven't had significant financial or logistical setbacks that put us behind schedule like in previous months.

Our reliable and hardworking manufacturing team has made our lives easier so that we can focus on more big-picture goals. The machinists we've hired are doing a great job, and our engineer, Sky, handles designs well.

"We've talked about it for years, … but when you give people jobs that they like and they're good at, you get more done. … And you have less on your plate as far as day-to-day tasks, which means that you can actually focus on the high-level forward-looking bigger decisions that you have to make." - R.T. Custer

The new employees have empowered us to focus on big-picture goals, and this is especially helpful because there are always new day-to-day challenges that have the potential to hold us back from making substantial progress. With our growing team, we can take on daily challenges while progressing with our many projects.

"Small projects around the shop are very disruptive, and it's nice to have another set of hands to do that stuff. And I mean, my list has gotten longer over the last two weeks for sure. ... Even though there's lots of stuff to do, all of the projects are kind of slowly moving forward. We're chipping away at everything." - Tyler Wolfe

Although we've been slow-moving with making headway toward completing our many small projects, we've been making consistent progress toward getting everything done.

"We have a lot of different projects working towards the big thing. … If we focused on just that one thing, we might feel like it's going really slow, and we want it to go faster. If you zoom out and you look at everything that's happening, it's really exciting because … everything's moving forward together, and it's towards this big goal." - R.T. Custer

The main overarching goal we are working toward is having a new watch in our American Artisan Series seven days a week. And we're making substantial progress because we now have enough hands on deck for Tyler to focus on keeping everything organized and running smoothly.

"With having multiple things going at once. It takes not only extra hands, but the freedom to … be able to orchestrate all of it. … If you're just inside all of these things and nobody is there to kind of have the overall picture, then that's [not] a recipe for success. … If you add hands and money to chaos, you're gonna get more chaos." - Tyler Wolfe

When running a business, you need to find out if you’re working in the business or on the business. If you're working in the business, you're focusing on completing the day-to-day procedures and completing tasks, while working on the business is about directing your overall strategy. You're thinking of the big-picture direction of your business rather than putting out fires and working on daily tasks.

As you scale your business and add more employees, you need to ensure that you're highly organized. Otherwise, your processes can become chaotic, and you'll have less direction for your company's goals.

Disadvantages of 3D Printing in Machining

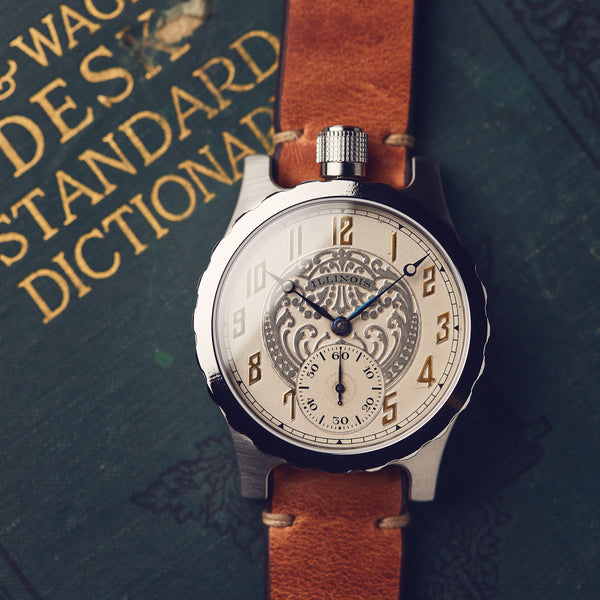

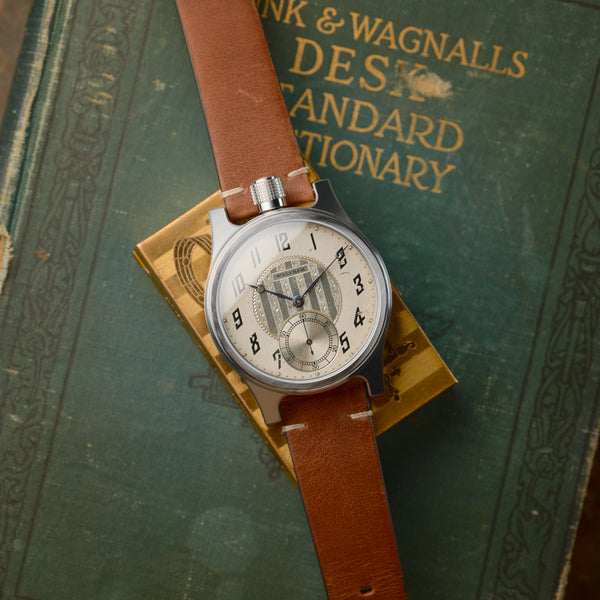

One small setback that we did have recently involved our first military prototype case. While assembling it, we discovered that the antique movement didn't quite fit. We've patinated the case and bezel and equipped it with a crown, but we need to make a new collet. After we fix this issue, our prototype should be perfect.

When working in the prototype stage, it may seem odd that we don't utilize our 3D printer to create models. At first glance, that may seem more efficient and less expensive than going straight into working with metal.

Although 3D printing is useful for creating plastic prototypes, it's not especially useful for our workflow because we've already created watch cases through the years.

"A lot of times when we think about using 3D printing to prototype a part, it's a part that can't be made with conventional manufacturing, or it's very difficult to make. And a lot of times it's a new thing, like a proprietary thing. [For example, they're useful if] we want to try a different way of setting up the valves or whatever. But for us, we've made a watch case before [so we don’t need to 3D print case prototypes]." - Tyler Wolfe

Our 3D printer is not especially useful when creating watch case prototypes because it cannot come up with the exact measurements we need.

"We wouldn't actually be able to trust any of the [findings] that we gain from the 3D printing [because] … our tolerances are plus or minus 0.01 millimeter. I don't know what the tolerances are [with the 3D printer], … [but it's] way more than that. So we can't really learn much about the technical side of the case from that. And it's also not made of the same material, and we can't patina it, so we also can't really get a great concept of how it looks." - Tyler Wolfe

Take a second to think about that size. There are 10 millimeters within a centimeter, and our watch tolerance is 1/100 of a millimeter! Although using a 3D printer allows us to see the overall shape of a prototype, our printer is incapable of displaying the exact measurements we need.

Our 3D printer still comes in handy for other tasks. For instance, if we aim to create something expensive that we haven't made before, 3D printing helps visualize our creations.

"What we do use it for is some fixturing type stuff. If it's a really hard, expensive fixture to make, we can kind of prove our concept before we go and make a metal version of fixturing." - Tyler Wolfe

Additionally, 3D printers are useful for creating organizational tools that enable us to continue our main work, such as customizable inserts for our bins. They’re also incredibly valuable for creating custom tools that aren’t available for purchase.

We don't utilize our 3D printer in the prototype stage of our watch cases, but the technology is still helpful for building certain items that don't require as low a tolerance.

How We’re Using Grant Money to Grow at Vortic

If you've been keeping up to date with watching or reading Custer & Wolfe, you'll likely recall that we had the honor of receiving a $250,000 machining grant. We're thrilled about receiving this money to create new jobs and stimulate the machining industry in Colorado, but certain logistical challenges come with receiving grant money.

Rather than receiving the money all at once, there's a rigorous procedure for allocating the funds.

"You don't just get a quarter million in cash deposited into your business bank account. It took about three months just to get the 40-page contract detailing how we get the money, how we ask for the money, how we get reimbursed, how we have to invoice, and how we have to keep our accounting. It's intense. I mean, it's state funding so it should be intense. They wanna make sure we're using it for the right thing." - R.T. Custer

When receiving a grant, you don't have free reign to spend the money however you want. You must abide by your grant proposal and use the money for proposed expenses. For example, some of our grant money went toward getting our new machines up and running. This included the purchase of the machine itself as well as setting up the machines and training.

In addition to going toward our equipment, setup, and training, the grant will also help us pay for some of our employees' salaries.

"The grant is gonna help reimburse us [for] our new machinist salary, … and [it will reimburse] part of … our engineer's salary. And so the point is to… help advance manufacturing in the state of Colorado. We're bringing in machines that not many people have here and doing things that not many people do here." - R.T. Custer

The state of Colorado awarded us the grant because we are bringing more machining work into the state. We are creating new machining jobs and will continue creating new ones as we expand.

Fortunately, in addition to being reimbursed, we will receive some of the grant money in cash that we can use for the Vortic Watch Company.

How to Learn More About Building a Watch Company

As always, we feel incredibly grateful to have the opportunity to create new jobs that people enjoy while also building an American-made watch company. We're excited to continue sharing updates with you as we get more experience under our belts with our new machines and as we continue growing our company.

Also, be on the lookout for our new American Artisan Series watches, and get ready for 2022 Military Edition watches! These watches will launch on November 11 at 12:00 PM MDT.

If you're interested in learning more about what it takes to build an American watch company, make sure to subscribe to the Custer & Wolfe YouTube channel. You can also follow us on Instagram, and you can sign up for our newsletter on our website to get watch info sent directly to your inbox.